Working Party on High Pressure Technology - WP HPT

Welcome to the website of the EFCE Working Party on High Pressure Technology.

Current activities

Recent event

7th International Symposium on High Pressure Technology

Maribor, Slovenia, 26-29 May 2024 (EFCE Event No. 807)

The event was organised by the EFCE Working Party on High Pressure Technology and held in conjunction with the 20th European Meeting on Supercritical Fluids.

Awards: Prof. Erdogan Kiran Graduate Student Support and ISASF Ph. D. Award

Spotlight Talks

| DATE | TOPIC / PROGRAMME | |

|---|---|---|

| 7 November 2024 | High pressure technologies for a sustainable energy sector |

Recording (YouTube) |

| 26 May 2023 | Technology to improve conventional chemical engineering processes | Recording (YouTube) |

BUSiness Meeting

tba

History and Mission of the Working Party

History

The Working Party (WP) on High Pressure Technology (HPT) of the European Federation of Chemical Engineering (EFCE) was established in 1988. Prof. Gerhard Vetter (University of Erlangen, Germany) was one of the founders of the WP HPT. The chairmen of WP HPT were as follows:

| Chair | Term of office |

|---|---|

| Prof. Dr. Gerhard Vetter (Erlangen, Germany) | 1988 - |

| Prof. Dr. Helmut Tiltsher (Munich, Germany) | |

| Prof. Dr. Gerhard Vetter (Erlangen, Germany) | |

| Prof. Dr. Alberto Bertucco (Padova, Italy) | 1997 - 2003 |

| Prof. Dr. Željko Knez (Maribor, Slovenia) | 2003 - 2010 |

| Prof. Dr. Eberhard Schlücker (Erlangen, Germany) | 2010 - 2021 |

| Prof. Dr. Maria José Cocero Alonso (Valladolid, Spain) | since 2021 |

Europe has been the cradle of high pressure technology in the 20s and 30s when most relevant high pressure chemical processes and plants were developed. The special scientific and technical knowledge required in this respect became a precious technological heritage of European Conutries. In the last two decaded the demand expertise in the field has increased considerably: both academic and industrial researchers from different ares (chemists, physicists, biologists, pharmacists, food technologists) have been involved in projects about high pressure applications to new processes and products.

Aims and objectives

Aims and objectives of the WP HPT are:

-

operation, coordination, promotion and advancement of high pressure research activities within Europe and co-operation activities beyond

-

active collaboration in the organisation of thematic sessions on HPT

-

coordination of international scientific events organised in Europe in the field of high pressure technology

-

establishment of closer co-operation within high pressure research groups at university and industry from different areas

-

education of phD students, researchers from universities and industry in the fundamentals and applications of high pressure technology in chemical and process industry: organisation of an intensive course.

-

active participation in the initiatives of the EFCE advisory board about DSCPT

Nowdays, the WP HPT has 21 members from 13 different countries , which hold one technical meeting per year, and are present at different events dealing with high pressure technology: international conferences, meetings, symposiums and other.

The WP contribution to Development of Sustainable Chemical and Process Technologies (DSCPT) involves substitution of organic solvents by the use of harmless compressed gasses, i.e. water and carbon dioxide at high pressure, in many applications of the chemical, food, pharmaceutical, biochemical, cosmetic, materials industries.

"High pressure is a wonderful tool to develop new processes and products".

Working Party Members

AUSTRIA

Prof. Dr. Thomas GAMSE (Delegate; WP Secretary)

Graz University of Technology

Institute of Chemical Engineering and Environmental Technology

Inffeldgasse 2, 8010 Graz

Tel: +43 316 873 7477

Contact

Dr. Eduard LACK (Honorary Member)

DI Martin SOVA (Delegate)

Natex Prozesstechnologie GesmbH

Werkstraße 7, 2630 Ternitz

Telefon: +43 699/171 38 019

Contact

CROATIA

Prof. Dr. Stela JOKIC (Guest Member)

CZECH REPUBLIC

Dr. Helena SOVOVA (Delegate)

Academy of Sciences of the Czech Republic

Institute of Chemical Process Fundamentals

Department of Diffusion and Separation Processes

Rozvojova 2, 165 02 Prague 6 - Suchdol

Tel: +420 220390 234, 23

Contact

http://www.icpf.cas.cz/sep/sep.aspx

FINLAND

Prof. Tapio SALMI (Elected Member)

Abo Akademi University

Laboratory Industrial Chemistry

Biskopsgatan 8, 20500 Turku / Abo

Tel: +358 02 2154427; Fax: +358 02 2154479

Contact

FRANCE

Ms. Elisabeth BADENS (Elected Member)

Aix Marseille University

Laboratory M2P2 UMR-CNRS 7340

Europôle de l'Arbois BP 80, Bat. Laennec Hall C, 13545 Aix-en-Provence cedex 4

Tel: +33 442 90 85 00 / 33 6 85 54 30 17; Fax: +33 442 90 85 15

Contact

Prof. Martial SAUCEAU (Guest Member)

Ecole des Mines d'Albi-Carmaux

Laboratoire de génie des procédés des solids divisés, UMR CNRS 2392

81013 Albi Cedex 09

GERMANY

Prof. Dr. Markus BUSCH (Elected Member)

Technical University Darmstadt

Alarich-Weiss-Strasse 8, 64287 Darmstadt

Tel.: +49-6151-1628190; Mob.: +49-171-1233444

Contact

http://buschlab.de or https://www.chemie.tu-darmstadt.de/busch/index.de.jsp

Prof. Dr.-Ing. Marcus PETERMANN (Delegate)

Ruhr University of Bochum

Feststoffverfahrenstechnik

Universitätsstr. 150, 44780 Bochum

Tel:+49-234 32-26442; Fax:+49-234 32-14277

Contact

Prof. Eberhard SCHLÜCKER (Delegate)

University of Erlangen

Institute for Process Technology and Machinery

Cauerstrasse 4, 91058 Erlangen

Tel: +49 9131 85 29450; Fax: +49 9131 85 29449

Contact

Prof. Dr.-Ing. Sabine GRÜNER-LEMPART (Elected Member)

University of Applied Sciences Weihenstephan-Triesdorf

Department of Bioengineering Sciences

Am Hofgarten 10, 85354 Freising

Tel: +49 8161 71-3842; Fax: +49 8161 71-5116

GREECE

Assoc. Prof. Dr. Epaminondas VOUTSAS (Guest Member)

HUNGARY

Prof. Edit SZEKELY (Delegate)

Budapest University of Technology and Economics

Department of Chemical and Environmental Process Engineering

Műegyetem rkp. 3., H-1111, Budapest

ITALY

Prof. Giuseppe CAPUTO (Delegate)

Università di Palermo

Dept. of Industrial and Digital Innovation (DIID)

Viale delle Scienze, ed.6, 90141 Palermo

LITHUANIA

Prof. Rimantas VENSKUTONIS (Guest Member)

Kaunas University of Technology

Radvilenu pl. 19, 50254 Kaunas

Contact

Laura JURIENE (Guest Member)

Kaunas University of Technology, Faculty of Chemical Technology

Radvilenu pl. 19, 50254 Kaunas

Contact

The NETHERLANDS

POLAND

Prof. Dr. Edward RÓJ (Delegate)

Lukasiewicz Research Network - New Chemical Syntheses Institute

Research Group Supercritical Extraction

Aleja Tysiąclecia Państwa Polskiego 13 a, 24–110 Puławy

Contact

Prof. Irena ZIZOVIC (Elected Member - Delegate status to be confirmed)

Wroclaw University of Science and Technology, Faculty of Chemistry

Norwida 4/6, 50-373 Wroclaw

Tel. +48 71 320 3425

Contact

Institutional link: https://pwr.edu.pl/en/

PORTUGAL

Prof. Dr. Manuel NUNES DA PONTE (Honorary Member)

Universidade Nova de Lisboa

FCT/UNL, Department of Chemistry

Quinta da Torre, 2829-516 Caparica

ROMANIA

Prof. habil. dr. Catinca SECUIANU (Delegate - to be confirmed)

Department of Inorganic Chemistry, Physical Chemistry & Electrochemistry

Faculty of Chemical Engineering and Biotechnologies

University Politehnica of Bucharest

Campus “Polizu”, 1-7 Gh. Polizu Street, Building E, Rooms 305-306

011061 Bucharest, District 1

Tel.: +40 21 402 3823/3988

Contact

SERBIA

Dr. Marko STAMENIC (Delegate)

Belgrade University

Faculty of Technology and Metallurgy

Karnegieva 4, 11000 Belgrade Serbia

Tel. +381 11 3303 710

Contact

Institutional link: http://www.tmf.bg.ac.rs

SLOVENIA

Prof. Dr. Željko KNEZ (Delegate)

Faculty of chem and chem Eng.

University of Maribor

Smetanova 17, 2000 Maribor

phone mobile: +386 41 371 666

Contact

SPAIN

Prof. Dr. María José COCERO ALONSO (Delegate; WP Chair)

Universidad de Valladolid

Dpto. Ingeniería Química y Tecnología del Medioambiente.

EII Sede Mergelina.

47011 Valladolid

Tel: +34 983 423174

Contact

Prof. Francisco RECARENS (Delegate / Honorary Member)

Universitat Politécnica de Catalunya (retired)

Contact

SWEDEN

Prof. Charlotta TURNER (Guest Member)

Lund University

Department of Chemistry

Organic Chemistry

P.O. Box 124, 22100 Lund

Tel: +46 46 222 8125; Fax: +46 46222 8125

Contact

SWITZERLAND

Dr. Beat H. ZEHNDER (Delegate)

SITEC-Sieber Engineering AG

Lohwisstrasse 46, 8123 Ebmatingen

Tel: +41 44 982 20 78; Fax: +41 44 982 10 79

Contact

TURKEY

Dr. Cerag DILEK (Guest Member)

Associate Professor

Chemical Engineering Department

Middle East Technical University

ODTÜ

Dumlupinar Bulvari No:1

06800 Çankaya Ankara/TÜRKIYE

Tel: +90-312-210 2626

Contact

https://che.metu.edu.tr/en/assoc-prof-cerag-dilek-hacihabiboglu

Prof. Dr. Can ERKEY (Delegate)

Koc University

Department of Chemical and Biological Engineering

Rumelifeneri Yolu, Sariyer, 34450 Istanbul

UNITED KINGDOM

Prof. Dr. Carl J SCHASCHKE (Honorary Member)

Glasgow Caledonian University

Dean

School of Computing, Engineering and Built Environment

Events

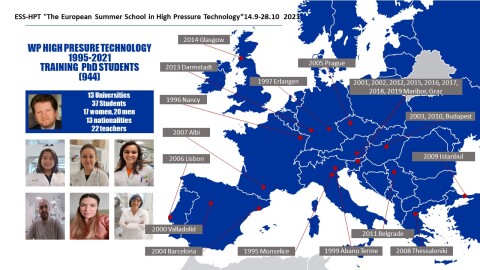

ESS-HPT "The European Summer School in High Pressure Technology"

7th International Symposium on High Pressure Technology

Maribor, Slovenia, 26-29 May 2024 (EFCE Event No. 807)

The event was organised by the EFCE Working Party on High Pressure Technology and held in conjunction with the 20th European Meeting on Supercritical Fluids.

Awards: Prof. Erdogan Kiran Graduate Student Support and ISASF Ph. D. Award

The members of WP HPT were present at following events:

ConferenceS

-

6th International Symposium on High Pressure Processes Technology - ISHPPT

-

International Congress of Chemical and Process Engineering - CHISA

-

Different Meetings and Conferences on Supercritical fluids and their applications organised by the International Society for the Advancement of Supercritical Fluids (ISASF)

Publications

High Pressure Process Technology: fundamentals and applications

Edited by:

A. Bertucco

Universita di Padova, Facolta di Ingegneria,

Via F. Marzolo 9, 35131 Padova PD, Italy

Email: Contact

G. Vetter

Universität Erlangen-Nürenberg, Lehrstuhl für Apparatetechnik und Chemiemaschinenbau,

Gauerstrasse 4, 91058 Erlangen, Germany

Hardbound, 684 pages, publication date: OCT-2001 (e-Book available, too)

ISBN-13: 978-0-444-50498-2

Imprint: ELSEVIER

For ordering (print and/or e-book) see: https://www.elsevier.com/books/high-pressure-process-technology-fundamentals-and-applications/bertucco/978-0-444-50498-2

Clear evidence of increasing demands in the processing industry prompted the editors and authors to publish a new book about High Pressure Process Technology: Fundamentals and Applications.

This book presents the latest knowledge regarding the high pressure processing aspects combined with that about the modeling, the design and the operation of safe and reliable high pressure plants and equipment. This treatment and selection of the subjects is stimulating and unique. Consisting of nine chapters, each subdivided into several sections, the book addresses the high pressure aspects, providing well selected correlated information connected with a comprehensive overview together with a large number of references.

The main body of the first eight chapters refers to subjects like high pressure in general, the thermodynamics and kinetics of the fluids involved, the design of high pressure equipment, the modeling and design of reactors, separation and fractionation units, the safety aspects, the control and economics.

In the extended last chapter, examples of promising high pressure applications are explained, such as chemical and enzymatic reactions in supercritical solvents, hydrogenation under supercritical conditions, supercritical water oxidation, polymerization with metallocene catalysts, supercritical extraction, fractionation and precipitation, supercritical pharma processing, ultra-high pressure sterilization and supercritical dry-cleaning.

Audience:

For all those interested in high pressure process technology, including chemical engineers, process engineers, pharmaceutical technologists, food technologists and bio-technologists.

Contents:

- Chapter headings.

- Selected papers.

Preface. Contents.List of Contributors. - Introduction.

High pressure: definitions and examples in nature. Early historical roots of high pressure technology. High pressure technology today - motivations for using high pressure. High pressure technology today - application survey and examples. - Thermodynamic Properties at High Pressure.

Introduction.Phase equilibria. Calculation of high pressure phase equilibria. Chemical reaction equilibria. Experimental methods. - Kinetic Properties at High Pressure.

Interesting features at high pressure. Kinetics of high pressure reactions. Measurement of chemical kinetic data at high pressure. Transport properties. - Design and Construction of High Pressure Equipment for Research and Production.

High pressure machinery. High pressure piping equipment. High pressure vessels and other components. Instrumentation of high pressure facilities. - Industrial reaction units.

Reactors for homogeneous reactions. Hydrodynamics and mass transfer in fixed-bed gas-liquid-solid reactors operating at high pressure. Slurry catalytic reactors. Catalytic reactors for olefin polymerizations. - Separation Operations and Equipment.

Pressure distillation. Packed towers: random and structured packings.Tray columns.Trays or packings? Conclusions for pressure distillation. Extraction from solids.Extraction from liquids. - Safety and Control in High Pressure Plant Design and Operation.

General safety aspects in high pressure facilities.Runaway of polyethylene reactors.Safety in high pressure extraction plants. - Economics of High Pressure Processes.

High pressure extraction plants. High pressure polymerization of ethylene. Precipitation by supercritical antisolvent. - Applications.

Chemical reactions in supercritical solvents (SCFs). Enzymatic reactions. Hydrogenation under supercritical single-stage conditions. Supercritical water oxidation (SCWO). Application to industrial wastewater treatment. High pressure polymerisation with metallocene catalysts. Supercritical fluid extraction and fractionation from solid materials. High pressure polymer processing. Precipitation of solids with dense gases.Pharmaceutical processing with supercritical fluids. Treating microorganisms with high pressure. Dry cleaning with liquid carbon dioxide. References.